Create peace of mind.Technological capabilities that create and continue to support safety and security.

Providing a one-stop solution for architectural steel frames.

We provide a consistent one-stop solution from pre-design consultation, design, material procurement, fabrication/painting/inspection, transportation, and on-site construction of architectural steel frames. The Yamagata head office factory boasts an area of 52,358 m² (1.1 times the size of Tokyo Dome) and has built a consistent production line for steel frame production. The factory premises include a material yard, a mobile painting shed, and a product yard of over 10,000 m². The factory has equipment for primary processing, assembly, welding, and can fabricate columns and beams simultaneously. In addition, we provide a one-stop service to meet a wide range of customer needs, including pre-design consultations for steel frames, preparation of drawings, and construction of manufactured steel frames. With over 150 years of history since our founding and technology and quality cultivated by the spirit of innovation, we will meet the high demands of our customers.

At our H-grade certified factory, we produce high-quality products that meet the exacting needs of our customers.

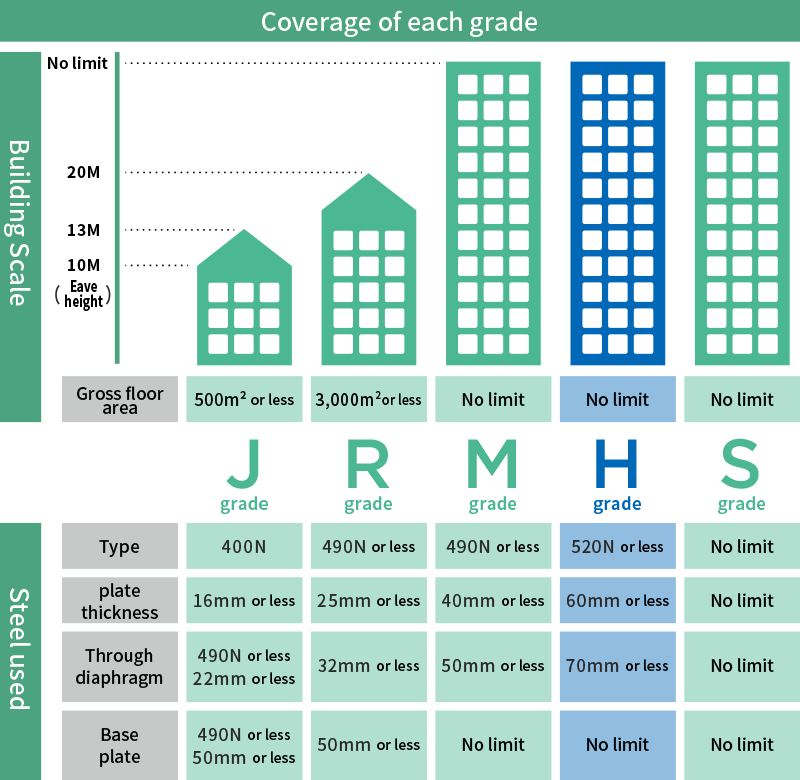

Steel frame manufacturing factories have a certification system that classifies them into five grades (S, H, M, R, J) according to the building scale and the steel materials used. Itagaki Corporation has received "H grade certification" from the Minister of Land, Infrastructure, Transport and Tourism out of this 5-level evaluation. Itagaki provides customers with safe and secure products based on H-grade technology and quality.

About H grade certification

Since 1981, Itagaki Corporation has acquired the “H grade” factory certification system. We have knowledge and experience in not only high-rise buildings but also all kinds of steel frame manufacturing, and we confidently respond to customer needs.

- What is H grade?

- The building scale that can be handled by the steel frame manufacturing factory changes depending on the grade acquired.

There are five grades, in order of S, H, M, R, and J. Only about the top 15% can obtain H grade, there are no restrictions on the building height or total floor area, and board thicknesses of 60 mm or less and diaphragms of 70 mm or less can be accommodated.

- About grade evaluation

- National Steel Evaluation Organization Co., Ltd.

https://www.zentetsuhyo.co.jp/appraise/grade.html

Over 150 years since its founding.

Challenge to become a company that contributes to the world from Yamagata.

In 1868, the first year of the Meiji era, he founded a blacksmith shop, the predecessor of the current Itagaki. Counting from there, we have carved out a long history of more than 150 years. The origin of our technology is the forging technology of blacksmiths. While firmly rooted in Shonai, Yamagata Prefecture, we entered the Tokyo area early on, and have refined our high quality and advanced processing technology while receiving orders for large-scale projects in Tokyo with a high degree of difficulty, including the Tokyo Sky Tree. We aim to be a company that contributes to the world by continuing to create people's safety and security, accumulating work that will remain in history and on maps.

Founded in the first year of Meiji(1868)

The origin of our technology is the forging technology of blacksmiths. In the history of more than 150 years since our founding, each of us feels close to our customers , actively working on modernization of production equipment such as mechanization and computerization, and technological innovation for making steel structures. I made progress day by day. While firmly rooted in Shonai, Yamagata Prefecture, we advanced to Tokyo from an early stage and have refined our high quality and advanced processing technology while receiving orders for large-scale projects in Tokyo with a high degree of difficulty.

Message from CEO

What we at Itagaki are trying to do is to read the customer's mind and make it properly.

It has been over 150 years since Bunjihei Itagaki started a forging business in Tsuruoka Kajimachi. As times change and technology innovates, Itagaki transforms itself with new strengths, creating superior products for the safety and security of the world.

We value technology and people. The Itagaki Group handles everything from steel frames for skyscrapers to water treatment plants. We want to make everyone shine through solid manufacturing.

If you want to display your favorite paintings, there is a suitable room for it. If you make a room, there is a house you want to live in. If you want to build that house, there is a city you want to live in. We are throwing our perspective to the universe, and we are working every day while imagining the safe and secure life and happiness of people on earth.

In order to realize a happy society, Itagaki will continue to make progress for our customers and human society in search of solutions that break down the impossible.

Management philosophy

- Improve technology and people, accumulate trust, and create customer value.

- We aim for the physical and mental happiness of all employees.

- Contribute to the safety and security of human society using iron.

Vision

We will contribute to the future of safe and secure living spaces for human society through excellent products and services.

Contact

If you have any questions or concerns, please feel free to contact us.

-

- +81-235-66-4711

- Telephone reception: Weekdays 8:00 to 17:00

-

- From the Mail form

- Contact us