Equipment

We have equipment that realizes integrated production and respond to customer needs.

Equipped with primary processing, shot blasting, beveling machine, column assembling device, rotating machine, automatic welding robot, large crane, large carrier, and mobile painting shed, we have an integrated production system that meets customer needs.

Equipment list

-

- Band saw

- 3 units

-

- Shirring

- 1 unit

-

- Portable automatic gas cutting machine

- 3 units

-

- Automatic gas cutting machine for circular cutting

- 5 units

-

- NC Multi-axis Drilling Machine

- 1 unit

-

- NC radial drilling machine

- 2 units

-

- Shot blast

- 2 units

-

- H-Steel Opening Machines

- 1 unit

-

- Steel plate beveling machine

- 1 unit

-

- Pillar size assembly device

- 1 unit

-

- reversal machine

- 3 units

-

- Arc welder

- 5 units

-

- Semi-automatic welding machine

- 42 units

-

- Connected Column Welding Robot

- 2 units

-

- Pillar large assembly welding robot

- 1 unit

-

- Portable Welding Robot

- 2 unit

-

- Surface thermometer

- 2 units

-

- Ultrasonic flaw detector

- 3 units

-

- Coordinate Measuring Machine

- 1 units

-

- Overhead traveling crane

- 15 units

-

- Single-leg bridge crane

- 10 units

-

- Portal crane

- 9 units

-

- Caterpillar type large carrier

- 1 unit

-

- Mobile painting shed

- 2 units

-

- CAD/CAM system Real4, Arris

- 7 units/27 units

-

- Photovoltaic module

- 384 sheets

-

CAD-CAM -

Material yard -

NC Multi-axis Drilling Machine -

Band saw -

H-Steel Opening Machines -

Connected Column Welding Robot -

Pillar size assembly device -

Pillar large assembly welding robot -

Pillar processing line -

Beam processing line -

Product yard (mobile painting shed) -

Carrying out

About H grade certification

Since 1981, Itagaki Corporation has acquired the “H grade” factory certification system. We have knowledge and experience in not only high-rise buildings but also all kinds of steel frame manufacturing, and we confidently respond to customer needs.

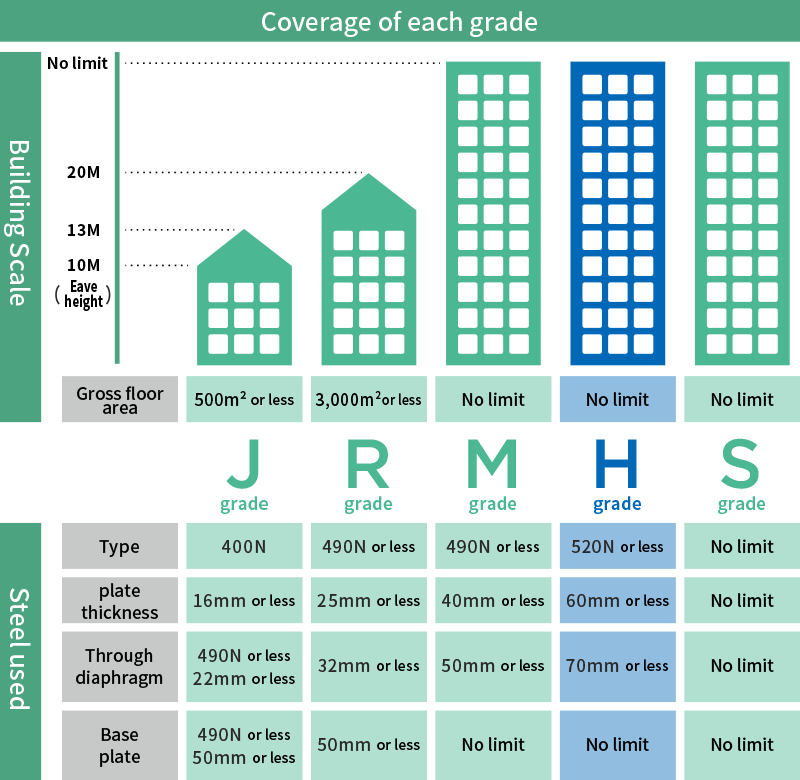

- What is H grade?

- The building scale that can be handled by the steel frame manufacturing factory changes depending on the grade acquired. There are five grades, in order of S, H, M, R, and J. Only about the top 15% can obtain H grade, there are no restrictions on the building height or total floor area, and board thicknesses of 60 mm or less and diaphragms of 70 mm or less can be accommodated.

- About grade evaluation

- Japan Steel Structure Evaluation Institute Co., Ltd.

https://www.zentetsuhyo.co.jp/appraise/grade.html

Environmental Initiatives

We have introduced a solar power generation system and

are taking environmentally friendly measures such as using argon gas.

Introduced a solar power generation system to reduce power consumption from fossil fuel sources by 15%.

A solar power generation system was introduced in 2021, and 384 modules were installed on the roof of the office building. Because Yamagata Prefecture is a snowy country, the amount of power generated decreases in winter, but it covers about 15% of the power used throughout the year. We will strive to combat global warming by reducing CO2 emissions.

Use of argon gas for welding reduces CO2 emissions by 80-90% compared to normal gas ratio.

Semi-automatic welding uses a mixed gas (argon gas 80%, carbon dioxide gas 20%) as shielding gas. Not only does it reduce spatter and improve the welding finish, but it is also environmentally friendly. Compared to carbon dioxide gas, CO2 emissions are reduced by 80% to 90%, and electric power consumption during welding is reduced by 10% to 15%.

Contact

If you have any questions or concerns, please feel free to contact us.

-

- +81-235-66-4711

- Telephone reception: Weekdays 8:00 to 17:00

-

- From the Mail form

- Contact us